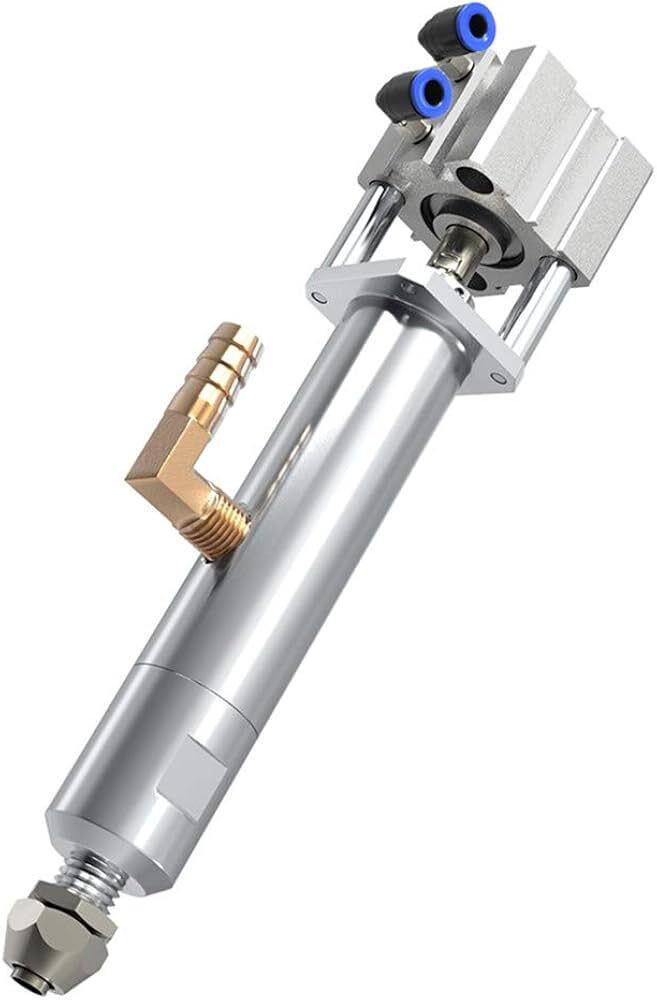

Compound Micrometer Dispensing Valve

Compound Micrometer Dispensing Valve Specification

- Structure

- Compact micrometer adjustable valve

- Material

- Stainless Steel

- Power

- Manual or Pneumatic

- Pressure

- 0-7 bar

- Media

- Liquid, adhesive, compound

- Working Temperature

- 0C to 60C

- Port Size

- 1/8 NPT

- Surface

- Polished

- Shape

- Cylindrical

- Application

- Precise dispensing of adhesives, liquids, and compounds in electronics and industrial assembly

- Leakage Rate

- Nil (Bubble tight)

- Weight

- Approx. 250 g

- Sealing Material

- PTFE

- Body Finish

- Corrosion-resistant

- End Connections

- Threaded

- Mounting Type

- Inline or panel mount

- Valve Type

- Needle type dispensing valve

- Repeatability

- High, suitable for micro-dispensing applications

- Dispensing Type

- Micrometer-controlled

- Control Method

- Fine adjustment manual control

About Compound Micrometer Dispensing Valve

Adhesive Dispensing Valve for small dispensing amount, shutting down form is sealed plastic thimble. can stop dispensing instantly.

Suit for low viscosity liquids, such as oil, epoxy, resin, UV, paint and so on.

Commonly used in the dispensing process 0.01-5g each time. can be used with solenoid valves or dispensing automatic controller

- Work pressure : 4-6 bar

- Minimum dispensing amount : 0.01ml

- Viscosity : <30000cps

- The main material : stainless steel

- Inlet pressure : 1-7bar

- Inlet size : 1/8" npt

- operating frequency : <60 point/min

- Dimensions : 130mm*21mm*21mm

- Maximum cartdridg pressure : 2 to 3 kg

Precision Micro-Dispensing Performance

Achieve exacting control over the dispensing of liquids, adhesives, and compounds thanks to the micrometer-controlled needle valve mechanism. Its fine adjustment manual control enables users to dial in precise flow rates for micro-dispensing applications, ensuring consistent results in high-tech assembly environments.

Durable Stainless Steel Construction

Crafted from polished, corrosion-resistant stainless steel, this dispensing valve is built to withstand demanding industrial conditions. PTFE sealing ensures chemical resistance and bubble-tight closure, which is vital for protecting delicate electronics and preventing process contamination.

Flexible Mounting and Integration

With inline or panel mounting options and standard 1/8 NPT threaded end connections, integrating the valve into existing dispensing setups is straightforward. Its compact cylindrical design allows for easy installation even where space is limited, making it suitable for a broad range of production lines.

FAQs of Compound Micrometer Dispensing Valve:

Q: How does the micrometer-controlled adjustment enhance precision in dispensing?

A: The micrometer-controlled adjustment offers finely-tuned manual control over the needle valve, allowing users to accurately set the desired flow rate for micro-dispensing. This ensures repeatable and consistent dosing of adhesives, liquids, or compounds, which is essential in electronics and sensitive industrial assembly processes.Q: What media can be dispensed using this needle type valve?

A: This valve is suited for dispensing a wide variety of media including liquids, adhesives, and compounds. Its corrosion-resistant stainless steel body and PTFE seals allow compatibility with chemicals commonly used in electronics manufacturing and industrial applications.Q: When should this dispensing valve be used over other types?

A: Choose this valve when you require high repeatability, leak-free performance (bubble tight), and precise micro-dosing. It is ideal for applications involving controlled dispensing of small volumes, especially in electronics assembly or other environments where accuracy and cleanliness are critical.Q: Where can the Compound Micrometer Dispensing Valve be installed?

A: It can be mounted inline or on a panel, depending on your system setup. The 1/8 NPT threaded connections make it compatible with a variety of dispensing arrangements in manufacturing, laboratory, or industrial automation settings.Q: What is the process for adjusting flow with this valve?

A: Flow rate is controlled manually through the micrometer adjustment. By turning the micrometer knob, the user precisely positions the needle within the valve seat, regulating flow from fully closed (bubble tight) to the desired dispensing rate. This process allows for instant fine-tuning during operation.Q: Is this valve suitable for high-pressure applications?

A: Yes, the valve is designed to handle pressures ranging from 0 to 7 bar, making it suitable for controlled dispensing environments where medium pressure levels are required.Q: What are the main benefits of using this micro-dispensing valve?

A: Key benefits include precise and repeatable dispensing, zero leakage (bubble tight), strong chemical resistance, flexibility in mounting, and durability thanks to its stainless steel and PTFE construction. These attributes ensure reliability and accuracy in critical industrial and electronic assembly processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dispensing And Metering Valve Category

Manual Small Flow Dispensing Valve

Price 6000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Dispensing Valve

Material : Aluminum

Color : Silver

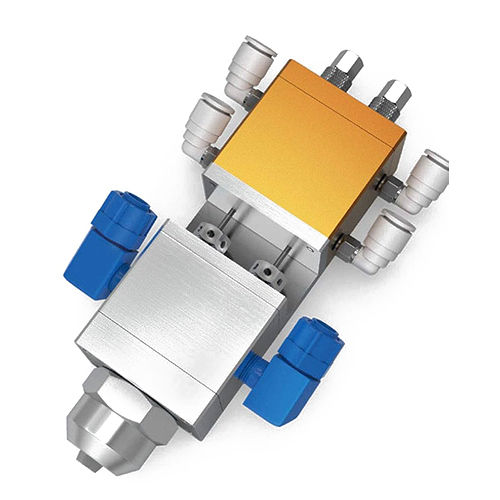

High flow Suck back type dispensing valve

Price 15000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : silicone dispensing

Product Type : Dispensing Valve

Material : Stainless Steel

Color : silver

Manual High Flow Dispensing Valve

Price 9000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Dispensing Valve

Material : Aluminum

Color : dark yellow

AB Glue Dispensing Valve

Price 28000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Dispensing Valve

Material : Stainless Steel

Color : Silver

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free